Injection Mold Set-Up (Plastic) Apprentice

Registered Apprenticeship

16 Credits | 4 Years

New Richmond

Students will complete a portion of their program at the St. Croix Manufacturing Skills Center.

Career Cluster: Manufacturing

What is an Apprenticeship?

A Registered Apprenticeship is a state-certified work-based training program that combines paid-related instruction and on-the-job training. Apprentices are trained under a written training agreement called an indenture. While indentured, the employer agrees to teach the apprentice the skills of the trade and the apprentice agrees to learn the skills involved.

Injection Mold Set-Up (Plastic) Apprentice Overview

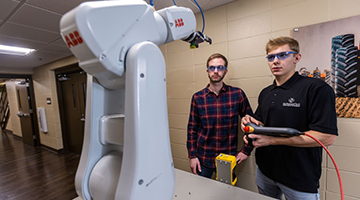

Injection molding machine setters set up and tend machines that transform plastic compounds into a wide variety of consumer goods such as toys, tubing and auto parts. They install plastic injection molds on the molding machine; make necessary connections of the electrical, hydraulic and cooling systems to the mold; ensure that the correct plastic material, plastic melt temperatures, shot size, injection speed and pressures are set; and cycle the machine and adjust the molding parameters until acceptable parts are produced.

Units of instruction include electricity, hydraulics and pneumatics; statistical process control; plastic mold design and blueprint reading; technical mathematics; basic tool room machine shop operations; and an overview of many of the plastic molding processes other than injection molding.

Program Outcomes

Injection Mold Set-up (Plastic) Apprentice completers will be able to:

- Classify the structure and properties of plastics

- Install (and maintain) molds

- Set-up injection molding machines

- Compare plastic processes used in the industry

- Analyze mold design and construction

- Interpret industrial prints and schematics

- Apply mathematics to industrial situations

- Solve problems by troubleshooting equipment components and processes

- Apply automation principles to injection molding and plastics

On-the-job learning is 90% of apprenticeships. Apprentices are full-time, paid employees trained by the employer's skilled workers.

Progressive wages are earned by apprentices as their skills grow. Wages are set by the employer. Apprentices are paid to attend related instruction.

Apprentices learn the theory and lab to support on-the-job learning.

Academics

Program Features

This four-year apprenticeship includes 7,744 hours of on-the-job training and 576 hours of paid related instruction

Transition to Trainer

The Transition to Trainer course is required for completion. Students will take this course the last year of the apprenticeship

Continuing Education

Graduates are able to apply program 39 credits towards the Technical Studies – Journeyworker associate degree program

Required Courses

The program required courses are state-approved and designed specifically to meet employer needs.

Featured Injection Mold Set-Up (Plastic) Apprentice Courses

Injection Mold Set-Up (Plastic) Apprentice is Part of a Career Pathway

As an Injection Mold Set-Up (Plastic) Apprentice student at Northwood Tech, you can earn credentials each step of the way!

You could take this first.

Injection Mold (Plastic) Certified Pre-Apprenticeship (CPA)

Continue to earn your apprenticeship.

Earn an Associate Degree.

Continue your education to earn a bachelor's degree.

Admissions and Tuition

To become an apprentice in the state of Wisconsin, one must first be indentured by the State Bureau of Apprenticeship Standards (BAS). To become indentured you must:

- Contact an employer on your own. Employment is a requirement of entering an apprenticeship.

- Once you have an employer / sponsor, contact the Bureau of Apprenticeship Standards to initiate the application process between you and your employer

See Requirements and Application for more details

Cost of Attendance

The Cost of Attendance (COA) is an estimate of the costs that you may incur while attending Northwood Technical College.

Estimated Total Program Tuition 2025-26*

Injection Mold Set-Up (Plastic) Apprentice

16 Credits | 4 years

$2,694

*Tuition is an estimate and does not include any miscellaneous fees for various courses, tools, books, supplies or uniforms. Program book costs are in addition to tuition and fees and vary depending on course selection and where the books are purchased or rented.

After the Northwood Tech Injection Mold Set-up (Plastic) Apprentice Program

Upon completion of the apprenticeship, you will receive a Certificate of Apprenticeship Completion issued by the Department of Workforce Development - Bureau of Apprenticeship Standards (DWD-BAS).